The bending force can be calculated from the sheet thickness die opening bend length and the ultimate tensile strength of the material.

Calculate tensile strength aluminum sheet.

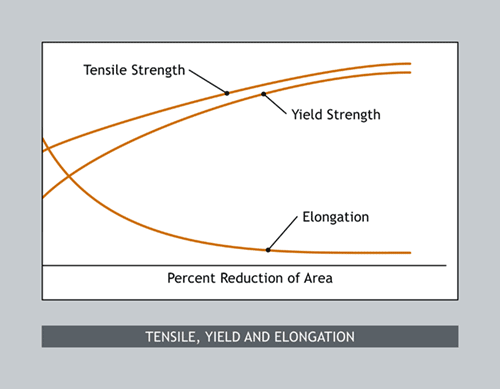

Tensile yield strengths and ductilities for some of the plain carbon and low alloy steels are given in the following mechanical properties of steel chart.

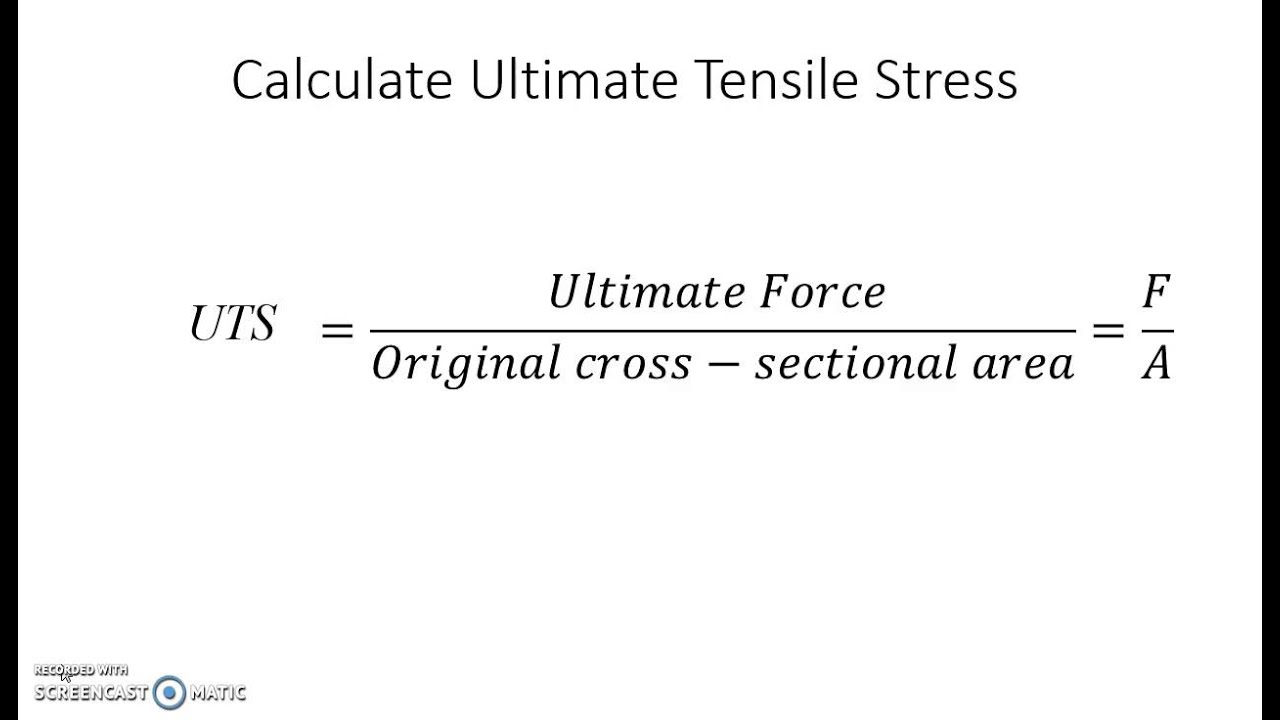

Below given the ultimate tensile strength formula to calculate the ultimate strength of any material.

The original shape is the flat sheet metal and formed components need to retain their shape permanently.

Copper magnesium silicon manganese and zinc are used as.

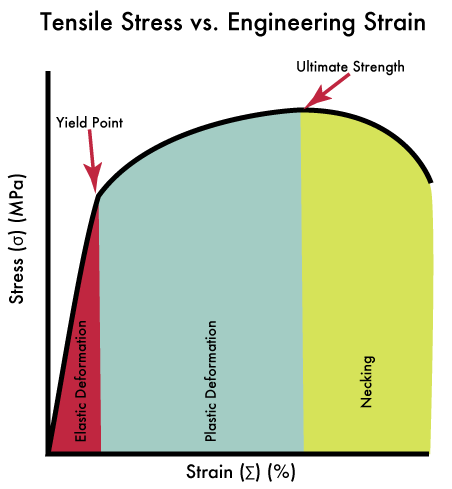

Strength of materials also called mechanics of materials is a subject which deals with the behavior of solid objects subject to stresses and strains.

In materials science the strength of a material is its ability to withstand an applied load without failure.

Aluminum sheet weight calculation material alloy steel aluminum beryllium brass bronze cast iron columbium copper copper alloys gold lead magnesium molybdenum nickel plastic silver stainless steel tantalum titanium tungsten zinc zirconium.

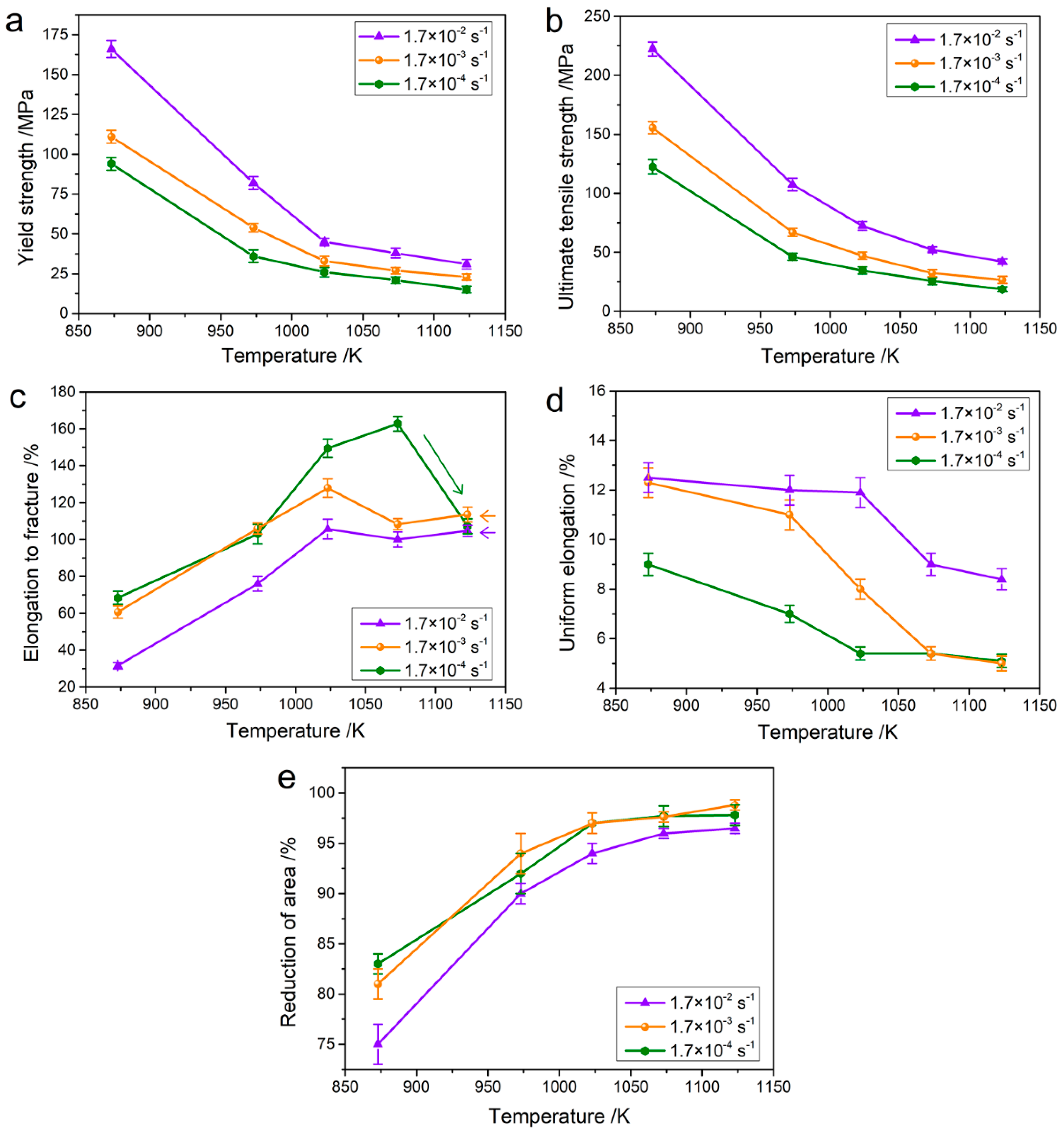

Aluminum has typical tensile strength between 40 mpa to 700 mpa.

Ultimate strength can be defined for liquids as well as solids under certain conditions.

The mechanical strength of aluminum can be increased by cold working and alloying.

Punch edge radius in.

Multiply the answer by the mild steel capacity of your machine to get the corresponding capacity of the machine.

Aluminum yield strength tensile strength and ductility values at room temperature are given in the following aluminum strength chart.

Yield strength tensile strength and ductility values for steels at room temperature.

The tensile strength is measured by the maximum stress that a material can withstand while being stretched or pulled before breaking.

Strength mechanics of material menu.

Ultimate tensile strength psi.

If the chosen sheet metal cannot be formed into the desired shape under the selected processing conditions the applied stresses are higher than the tensile strength of the sheet metal which causes cracks to form in the part.

Die edge radius in.

Divide 55 ksi by the tensile strength number associated with the type of aluminum or stainless steel you use the answer will be 1 for aluminum and 1 for stiainless steel.